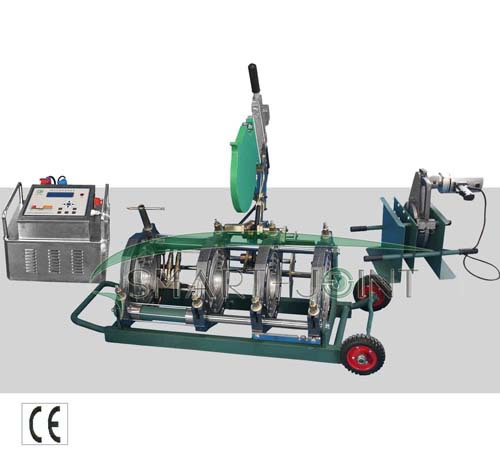

AFM250-AFM315 Automatic Butt Fusion Welding Machine

Inquire NowDescription

AFM250-AFM315 automatic butt fusion welding machine is a newly developed product provided by Songjiang Smart Joint Company. It is suitable for welding PE plastic pipes and pipe fittings with the size of 90 mm to 315 mm. This kind of automatic butt fusion machine minimizes the influence of man-made factors in the welding process to the maximum, ensuring high welding quality.

Manufacturing Standards

There are many manufacturing standards for automatic butt fusion welding machines. Because there is no ideal nondestructive detection method for the welding interface of plastic pipe, it is the basic guarantee to strictly implement the welding specification so as to ensure the welding quality of butt fusion machines.

1. ISO12176-1: Basic Functional Requirements of Fully Automatic Welding Machine Specified by International Plastic Pipes and Fittings-Equipment for Fusion Jointing Polyethylene Systems

2. GB/T200674.1-2006: Basic Functional Requirements of Fully Automatic Welding Machine Specified by China Plastic Pipes and Fittings-Equipment for Fusion Jointing Polyethylene Systems

Features of Automatic Butt Fusion Machine

1. Automatic butt fusion welding machines are designed with unique structure, which makes welding more safe and reliable.

2. The machine is configured with wheels, so it is easy to move.

3. It can store up to 1000 welding records.

4. Automatic butt fusion welding machines are appreciated for high cost performance and wide range of application.

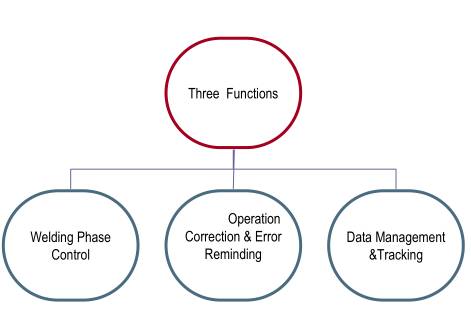

Functions

Automatic butt fusion machine can realize three functions on the basis of common welding machines: automatic control of welding sequence or welding phase control, operation correction and error reminding, welding data management and tracking. Welding phase control is the core function. Sequential process parameters of automatic butt fusion welding machine include welding temperature (T) and the pressure (P) on the welding interface in different welding phases or time (t).

Welding Process Control

Welding process control of automatic butt fusion machine is as follows:

1. Automatically control the milling pipe end face.

2. Automatically detect whether pipe is clamp or not.

3. Manually inspect the pipe’s unfitness of butt joint or alignment tolerance and adjust it.

4. Automatically and precisely detect the dragging pressure.

5. Automatically control the loop height.

6. Automatically control the heat absorption time.

7. Automatically limit the conversion time (There are two methods to take out the heating plate: automatic pop-up or manually.).

8. Automatically control the pressure boosting process.

Jilin Songjiang Lanteky Smart is a professional manufacturer and supplier of automatic butt fusion welding machines in China. In addition to this kind of butt fusion machine, we also produce eletrofusion welding machines, electrofusion fittings, butt fusion fittings, PE transitional fittings, fusion welding machine kits, and so on. With high quality assurance, our products are exported to the United States, UAE, Egypt, Australia, Brazil, Poland, Germany, Canada, Malaysia, New Zealand, Iran, Israel, Japan, and so on. If you are interested in our automatic butt fusion welding machines, you can visit the company’s website or contact us directly.

- FM355 Butt Fusion MachineFM355 butt fusion machine or butt fusion welding machine can be used to weld different sizes of pipes. It can also be used to weld pipes to fittings. The welding range of this machine is from Φ110 mm to Φ355 mm...