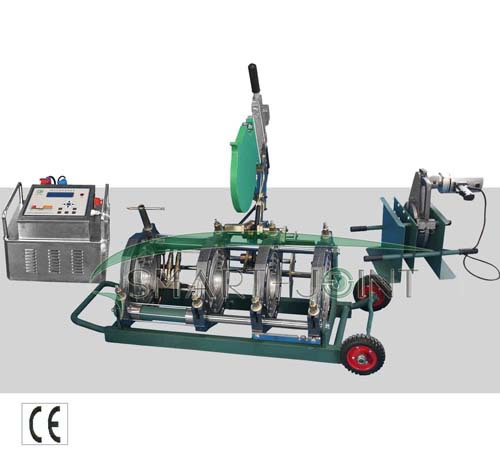

- Hydraulic Butt Fusion Welding MachineHydraulic butt fusion welding machine can be used for welding plastic materials like polyethylene (PE), polypropylene (PP), polyvinylidene fluoride (PVDF) and many other thermo-plastic materials...

- FM2000 Large Diameter Butt Fusion Welding MachineSongjiang Smart Joint Company began to design and produce FM2000 large diameter butt fusion welding machine in 2009. With rich production experience, we are able to manufacture various sizes...

- AFM250-AFM315 Automatic Butt Fusion Welding MachineAFM250-AFM315 automatic butt fusion welding machine is a newly developed product provided by Songjiang Smart Joint Company. It is suitable for welding PE plastic pipes and pipe fittings with the size of 90 mm to...

- FM355 Butt Fusion MachineFM355 butt fusion machine or butt fusion welding machine can be used to weld different sizes of pipes. It can also be used to weld pipes to fittings. The welding range of this machine is from Φ110 mm to Φ355 mm...

Butt Fusion Welding Machine

Introduction

Songjiang Smart Joint Company mainly produces hydraulic, large diameter and automatic butt fusion welding machines. We developed automatic hot melting welding machines in 2009, such as AFM250 and AFM315 pipe welding machines. It is suitable for butt welding of plastic pipes and fittings made of PE, PP and PVDF in construction site or workshop. This kind of butt fusion machine is mainly applied to household appliances, lights and other plastic welding.

Competitive Advantages

1. The welding process of hot melting welding machines is programmed in the controlling center. The operator is supposed to input pipe diameter, SDR (Statistical Data Recorder) and material grade, and then he is guided for each step by the controlling center. Thus the whole welding process of butt fusion welding machines can be finished and recorded correspondingly.

2. According to different sizes of plastic parts, we can set heating power and die size to achieve various plastic welding.

3. To improve the welding quality, all welding operation steps of hot melting welding machines are required to be measured precisely.

4. Low starting pressure of this butt fusion welding machine ensures reliable welding quality of small pipes.

Performance

1. Hydraulic unit is equipped with clamp moving control, pressure release button, pressure regulation valve, manometer and accumulator. It can control the pressure in each phase precisely.

2. Hot melting welding machine is equipped with four main clamps with the third clamp axially moved and adjusted.

3. Our butt fusion welding machines possess removable PTFE (Polytetrafluoroethylene) coated heater with separate temperature control system.

4. The automatic control system uses programmable controller (PLC) and touch screen human-computer interface to control. Each cylinder movement is driven by air pressure. Our hot melting welding machines are featured with simple operation, reliable performance, compact size, high welding efficiency and quality.

5. Made of lightweight and high strength materials and with simple structure, butt fusion welding machine is convenient to operate.

6. Separate two-channel timer shows time in soaking and cooling phases.

7. With highly accurate and shockproof pressure meter, our hot melting welding machines can indicate clearer readings.

Working Principle

The working principle of butt fusion welding machine is to heat two surfaces to a designated temperature, and then fuse them together by application of force. This pressure causes flow of the melted materials, which causes mixing and thus fusion. When the polyethylene material is heated, the molecular structure is transformed from a crystalline state into an amorphous condition. When fusion pressure is applied, the molecules from each polyethylene part mix. As the joint of the hot melting welding machine cools, the molecules return to their crystalline form, the original interfaces are gone, and the two pipes become one homogeneous unit.

Subclass Products

1. FM160/FM250/FM315 Hydraulic Butt Fusion Welding Machine

2. FM2000 Large Diameter Butt Fusion Welding Machine

3. AFM250-AFM315 Automation Butt Fusion Welding Machine

4. FM355 Butt Fusion Machine

Songjiang Smart Joint Company has a professional team for product quality, development and after-service. Our company becomes “Technical Support Unit” and is titled as “National Plastic Pipe Fittings Manufacturer” in China. Our hot melting welding machines have been exported to the United States, UAE, Egypt, Australia, Brazil, Poland, Germany, Canada, Malaysia, New Zealand, Iran, Israel, Japan, and so on. If you have interest in our butt fusion welding machines, please feel free to contact us.